application of charpy impact test in industry|charpy impact test formula : purchasing Material impact toughness can be measured by various types of test such as the Charpy V-notch impact test, Izod test or K IC test. The most commonly used test is the Charpy impact test .

About this item. 【20W PD 3.0 Fast Charger】20W PD 3.0 fast charger and 6ft USB-C to C cable, charge iPhone 15 to 55% in half an hour, which is 3× faster than with an original .

{plog:ftitle_list}

Resultado da Indianara Jung @indianarajung. I am a brazilian model with a liberal life and i will show you here everything I like to do!! 3 Following 50 Followers. Vids Items Custom Club. All (10) 20% Off. 09:33. I .

In forging industry, the Charpy impact test can be used to determine the malleability and ductility of a material that is being forged. In the rubber industry, the test can be used for determining the shock absorbing ability of a type of rubber so that its proper application could be decided.Applications of Charpy Impact Test. In forging industry, the Charpy impact test .

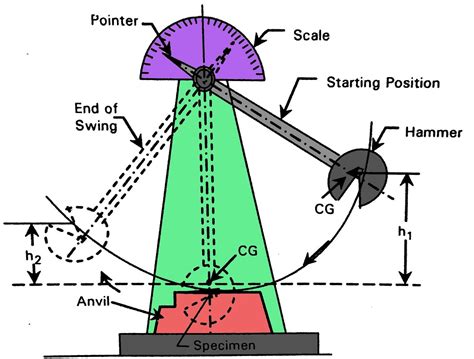

The Charpy impact test, also known as the Charpy V-notch impact test, measures the energy a material absorbs when it fractures under an impact load. A pendulum in a Charpy impact test .Charpy impact testing is a method used to determine the toughness or impact resistance of materials, particularly metals. It measures the amount of energy absorbed by a material during fracture, providing valuable insight into its . Charpy impact testing is a low-cost and reliable test method which is commonly required by the construction codes for fracture-critical structures such as bridges and pressure .

Material impact toughness can be measured by various types of test such as the Charpy V-notch impact test, Izod test or K IC test. The most commonly used test is the Charpy impact test . The Izod and Charpy impact testers are commonly used in the following industries and applications: Aerospace : The aerospace industry uses these tests to measure the impact resistance of various materials used in .

The charpy impact test of steel pipes has a wide range of applications. Aerospace Industry: Charpy impact tests can be used to assess the impact loads that aircraft structures and .

For more than 100 years, scientists have tested the impact resistance of metals used in construction by employing an apparatus called a Charpy machine. This device has a long, weighted arm that swings like a .The Charpy test is a standardized procedure designed to measure the energy absorbed by a material during a sudden impact load. This evaluation method assesses the material's .

charpy impact testing procedure

sebbag schirmer tear test repeat

In materials science, the Charpy impact test, also known as the Charpy V-notch test, is a standardized high strain rate test which determines the amount of energy absorbed by a .Applications of Charpy Impact Test. In forging industry, the Charpy impact test can be used to determine the malleability and ductility of a material that is being forged. In the rubber industry, the test can be used for determining the shock absorbing ability of a type of rubber so that its proper application could be decided.

Applications of Charpy Impact Test. In forging industry, the Charpy impact test can be used to determine the malleability and ductility of a material that is being forged. In the rubber industry, the test can be used for determining the .Applications: The Charpy Impact Test is more commonly used in the steel industry, while the Izod Impact Test is more commonly used in the plastics industry. Overall, both tests provide valuable information about a material’s . An Izod impact testing apparatus — which is essentially identical to a Charpy impact testing machine — is used to determine Izod impact strength. The primary differences between the Izod and Charpy impact tests are the size of the test specimen, how it is restrained, and which side is struck by the pendulum hammer.

The Charpy impact test is carried out in a 3-point flexure setup.The Charpy specimen is centered on the supports in the pendulum impact tester and rests against two anvils. In the case of notched specimens, the notch faces away from the pendulum hammer and is placed exactly across from the point at which the hammer strikes the specimen.The impact strength of a material is an important characteristic for applications in pipeline construction and shipbuilding. . This type of test is often used in the steel industry during the manufacturing of pipes as well as for the inspection of pipes. . In a Charpy impact test to ISO 148-1, a notched metal specimen is severed using a .

selected tear film tests in healthy cats

The Charpy impact test, also known as the Charpy V-notch test, is a high strain-rate test that involves striking a standard notched specimen with a controlled weight pendulum swung from a set height. The impact test helps measure the amount .IMPACT TESTING MATTERS, NOW MORE THAN EVER 1.1 What is a Pendulum Impact Test An impact test determines a material’s resistance to an impact event. It measures the amount of energy the material absorbs when it is hit by a high-rate load. The most common impact test methods are Charpy and Izod and are typically run using a pendulum impact tester.Tensile impact test procedures. The tensile impact strength test was originally developed to overcome the deficiencies of flexural (both Izod and Charpy) impact test. All the test variables that have a high effect on the results, such as notch sensitivity, toss factor and specimen thickness, are eliminated in the tensile impact test. Charpy impact testing determines the impact energy of materials. The test procedure, the application of charpy testing, factors affecting impact energy, the ductile to brittle transition are all covered. . How Plasma Will Revolutionize the Semiconductor Industry. Dr. Robert Hicks.

In forging industry, the Charpy impact test can be used to determine the malleability and ductility of a material that is being forged. In the rubber industry, the test can be used for determining the shock absorbing ability of a type of rubber so that its proper application could be decided.Charpy to ISO 179-1 is the preferred test method on plastics within the standard for single-point data ISO 10350-1. The test is ideally performed on unnotched specimens with edgewise impact (1eU). Should the specimen not break during the test, any subsequent tests are performed with notched specimens.

The Charpy impact test can adequately detect this brittle-toughness transition temperature, providing key data on the material’s limits of use. . Some of the primary application areas of the Charpy test include: Materials testing; . Demand for chip technology is both driving the industry as well as hindering it, with current chip . History of the Charpy impact test. The history of Charpy V-notch impact testing dates back to the early 1900s when French engineer Georges Charpy developed a standardized method for testing the impact toughness . Applications of Charpy Impact Test. In the forging industry, the Charpy impact test can be used to determine the malleability and ductility of a material that is being forged.

The charpy impact test of steel pipes has a wide range of applications. Aerospace Industry: Charpy impact tests can be used to assess the impact loads that aircraft structures and components may encounter during flight.This has an important impact on the safety and durability of the aircraft. Materials science research: In the development process of high-strength steels .Table 1. Summary of the mechanical properties for material A and B by normal tensile testing, instrumented impact testing and the key results forwarded by FBA method. No. Conventional Tensile .When you're delving into the world of material testing, two names often stand out: Izod and Charpy impact tests. At first glance, they might seem like distant cousins in the vast family of engineering, but as you look closer, their unique characteristics and purposes become as clear as the difference between silk and satin. These tests, pivotal in determining the toughness of . Charpy Impact Test. One of the most common types of impact testing is the Charpy impact test. This method involves striking a notched specimen with a pendulum hammer and measuring the amount of energy absorbed by the material before it fractures. The results are typically reported as energy absorbed in joules (J) or foot-pounds (ft-lbs).

We can support all types of impact testing, from pendulum impact, falling dart and falling weight impact testing through to low temperature brittleness testing. Our machines support several different methods and approaches to impact testing. A short description of some of these follows: Charpy and izod strength impact testing

Forging industry- The Charpy test is used in the metal (including steel) forging industry to determine the ductility and malleability strength and quality of materials that are being forged to .

The value of energy absorbed is read directly from a dial on the machine. A typical impact testing machine is shown in Figure. 1. Figure 1. Schematic of a Typical Charpy Impact Testing Machine. In carrying out a test, the specimen is loaded into the anvil with a pair of special tongs that facilitate location of the specimen in the machine.

For a comprehensive solution to test impact toughness in metals, our Charpy Impact Tester for Metals is designed to meet ASTM E23 standards, ensuring high-quality and reliable results. If your focus is on plastics or polymers, the Charpy Izod Pendulum Impact Tester for Plastics is perfect for assessing the toughness of non-metal materials.It is a pendulum-type single-blow impact test that involves the use of a notched test piece, which will be tested by either of the two techniques, namely the Izod test and Charpy test. In this scenario, Tinius Olsen comes as a game changer with its impact testers with a testing capacity of up to 542 J, quality testing, superior data acquisition .

In materials science, the Charpy impact test, also known as the Charpy V-notch test, is a standardized high strain rate test which determines the amount of energy absorbed by a material during fracture.Absorbed energy is a measure of the material's notch toughness.It is widely used in industry, since it is easy to prepare and conduct and results can be obtained quickly and . The Charpy impact test (Charpy V-notch test) is used to measure the toughness of materials under impact load at different temperatures! Test setup and test procedure. In the Charpy impact test, a notched specimen is abruptly subjected to bending stress. The specimen is usually 55 mm long and has a square cross-section with an edge length of 10 mm.

charpy impact testing methods

self acl tear test

Cornélio Procópio, Paraná, Brasil Weather Forecast, with current conditions, wind, air quality, and what to expect for the next 3 days.

application of charpy impact test in industry|charpy impact test formula